In modern manufacturing, the dispensing head, as a critical precision tool, is widely used in electronics, automotive, medical, and other fields. Not only does it improve production efficiency, but it also ensures the stability of product quality. This article will detail the advantages, application scenarios, and key points of selecting dispensing heads to help you better understand this important equipment.

The greatest advantage of dispensing heads lies in their high precision and high efficiency. Traditional manual dispensing methods are not only time-consuming and labor-intensive but also prone to errors that can affect product quality. In contrast, dispensing heads, through automated control systems, can achieve precise dispensing operations, ensuring that each drop of adhesive accurately falls in the designated position.

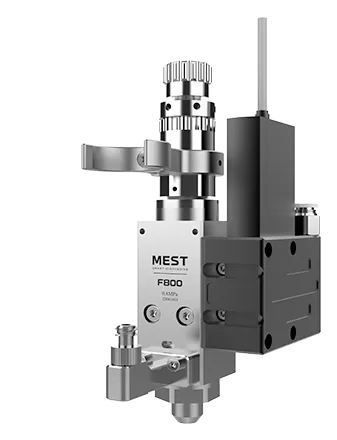

High Precision: Dispensing heads use advanced control technology to precisely control the flow and position of the adhesive, with error ranges typically at the micron level. This is particularly important for the manufacturing of electronic components that require high precision dispensing.

High Efficiency: Automated dispensing heads can operate continuously, greatly improving production efficiency. Compared to manual operations, automated dispensing heads are not only faster but can also work non-stop for 24 hours, significantly boosting the production capacity of the assembly line.

Dispensing heads have wide applications across multiple industries, especially in sectors with high precision requirements such as electronics, automotive, and medical.

Electronics Industry: In the manufacturing of electronic components, dispensing heads are widely used in processes such as chip packaging and PCB board dispensing. High-precision dispensing heads ensure the even distribution of the adhesive, preventing circuit short circuits or component damage due to uneven adhesive distribution.

Automotive Industry: In automotive manufacturing, dispensing heads are used for bonding and sealing parts such as car lights and windows. Efficient dispensing heads not only improve production speed but also ensure the firmness and tightness of the bond, enhancing the overall quality of the vehicle.

Medical Industry: In the production of medical devices, dispensing heads are used for the bonding and packaging of precision parts. High-precision dispensing heads ensure that each drop of adhesive falls accurately in the designated position, ensuring the safety and reliability of medical devices.

Choosing the right dispensing head is crucial for production efficiency and product quality. Here are several key factors to consider when selecting a dispensing head:

Precision Requirements: Select the appropriate dispensing head precision according to the specific application scenario. For high-precision electronic component manufacturing, a dispensing head with a micron-level error range is necessary.

Adhesive Type: Different adhesives have different viscosities and flow properties, requiring matching dispensing heads. For example, adhesives with higher viscosity need dispensing heads with adjustable output to ensure uniform dispensing.

Production Speed: Choose the appropriate dispensing head based on the speed requirements of the production line. High-speed production lines need dispensing heads with fast and stable output to ensure production efficiency.

In conclusion, as an important tool in modern manufacturing, dispensing heads bring great convenience to various industries with their high precision and high efficiency. By understanding the advantages, application scenarios, and selection points of dispensing heads, you can better choose and use this key equipment to enhance production efficiency and product quality.