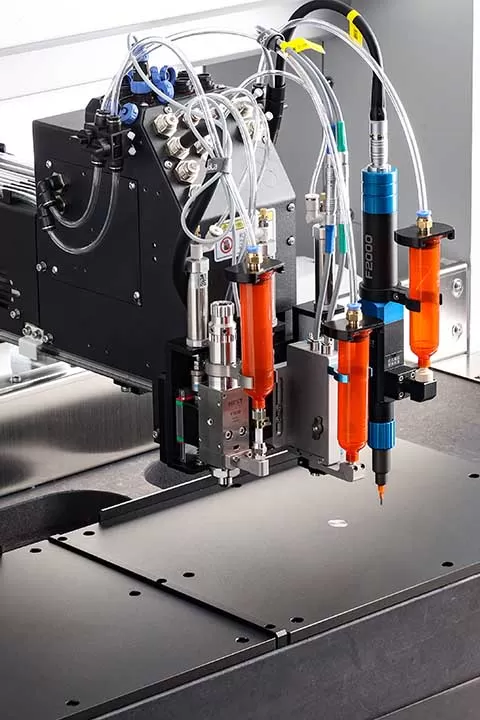

A vacuum feeder is designed to prepare and process materials in a vacuum environment to ensure high-quality results for sensitive applications. It typically works by removing air and entrapped gases from materials like adhesives, resins, or sealants to eliminate bubbles and voids that could compromise the product's integrity.

The process often involves mixing or degassing under reduced pressure, which enhances material homogeneity, improves bonding strength, and prevents defects during dispensing or molding. Vacuum systems are crucial in industries like electronics, aerospace, and medical devices where precision and reliability are paramount.

By removing air and trapped gases, it ensures material homogeneity, critical for adhesives, resins, and sealants.

Degassing enhances the consistency and performance of materials, leading to better adhesion and structural integrity.

Vacuum systems allow precise preparation of materials, reducing defects in high-precision applications.

Ideal for sensitive industries like electronics, aerospace, and medical devices, it ensures consistent and reliable results.

By ensuring proper material preparation, waste due to defects is minimized.