Basic selection level: Determine the material (Hastelloy/PEEK) of the metering valve according to the corrosiveness of the medium (such as acid/alkali concentration), select the valve core structure (needle valve/ball valve) according to the flow range (0.1-500mL/min), and match the pressure level (needle valve/ball valve) (needle valve/ball valve must exceed the peak pressure of the pipeline by 20%).

Performance verification level: Chemical metering pumps manufacturer can be required to provide a third-party test report with ±0.5% repeatability, verify the FDA/CE certification of the seal (especially for food/pharmaceuticals), and measure the dynamic response time (critical for pulse filling scenarios).

Integration adaptation level: Confirm that the control signal (4-20mA/Modbus) is compatible with the existing PLC, reserve the position of the pressure relief port (to prevent chemical crystallization blockage), and evaluate the maintenance window (such as ultrapure water conditions require a disassembly and cleaning cycle of ≤6 months).

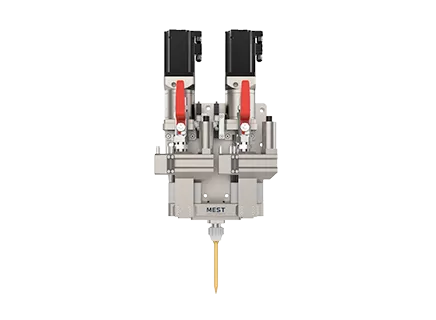

MEST chemical metering pump provides accurate, consistent flow rates, ensuring precise material dispensing.

By dispensing exact amounts, the metering pumps minimize material waste, improving efficiency and cost-effectiveness.

MEST chemical metering pump can handle a wide range of fluids, including adhesives, sealants, and lubricants, with varying viscosities.

Our metering pumps support high-speed, continuous operation, increasing overall production efficiency.

These chemical metering pumps can be easily integrated into automated production lines, streamlining processes and reducing manual labor.

Material Selection and Inspection

The foundation of our metering valve and metering pump QC process lies in material selection and inspection. We source materials from reputable suppliers, and each batch undergoes rigorous testing to ensure conformity to specifications.

Manufacturing Process Control

Our manufacturing process of metering valve & metering pump is monitored under statistical process control. Regular calibration of machinery and equipment ensures that all components are produced to precise tolerances, and thus reducing variability.

Assembly and Integration

Assembly is conducted by trained technicians following detailed standard operating procedures, ensuring consistency and precision.

Functional Testing

Each metering pump undergoes comprehensive functional testing to verify that it performs well, a step essential for ensuring operational reliability.

Leakage Testing

Leakage testing is performed using pressure decay methods to check for any leakage when the valve is closed, ensuring no detectable leakage.

Final Inspection

A final visual inspection is conducted to ensure there are no defects or damage, and all test results are reviewed to confirm the pump meets all specifications.

Initial Consultation and Requirements Gathering

The process begins with a detailed discussion with the customer to understand their specific requirements such as flow rate, pressure, fluid type and temperature range.

Feasibility Study

The metering valve engineering team conducts a thorough feasibility study to determine if the requested specifications can be achieved with existing technology and capabilities, including preliminary design and calculations.

Design & Engineering

Once the project is feasible, engineers design the metering valve, create a detailed CAD model, select appropriate materials, and define the manufacturing process.

Prototyping

Prototypes are produced to test the design and ensure it meets the customer's requirements, a step that helps to identify and resolve problems before full-scale production.

Testing and validation

Prototypes undergo rigorous testing, including flow accuracy, pressure handling, durability, and fluid compatibility tests to ensure good performance under a variety of conditions.

Manufacturing

After design verification, pneumatic metering valves are manufactured to specification, using state-of-the-art facilities and skilled technicians to ensure that each component meets the highest standards.