Ensure compatibility with the fluid’s viscosity, abrasiveness, and reactivity to prevent clogging or degradation.

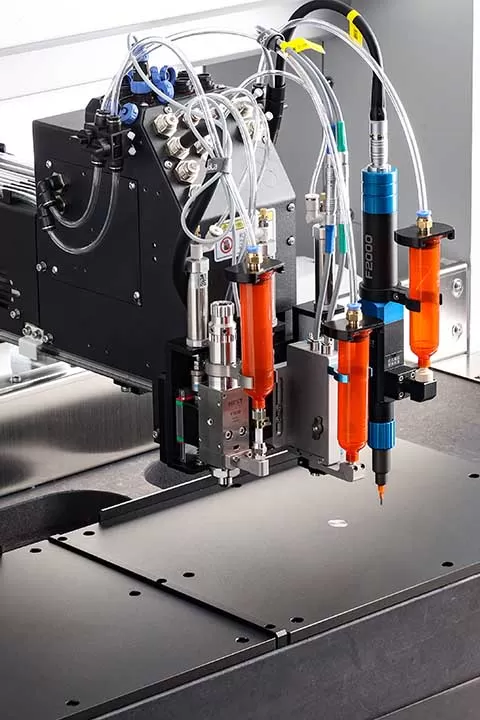

Define precision, dispensing patterns, and speed to match production goals.

Account for temperature, humidity, and cleanroom requirements.

Ensure compatibility with existing automation systems and workflows.

Design for future capacity needs and ease of cleaning or part replacement.

Adhere to industry standards and safety regulations.

Customized systems are designed to meet specific business needs, ensuring optimal performance and efficiency.

They can be easily scaled to accommodate business growth, unlike standard systems which may require significant modifications.

Unique features and functionalities can provide a competitive edge in the market.

Customized systems can seamlessly integrate with existing tools and processes, reducing disruptions.

While the initial investment may be higher, long-term savings are realized through improved productivity and reduced need for additional software.