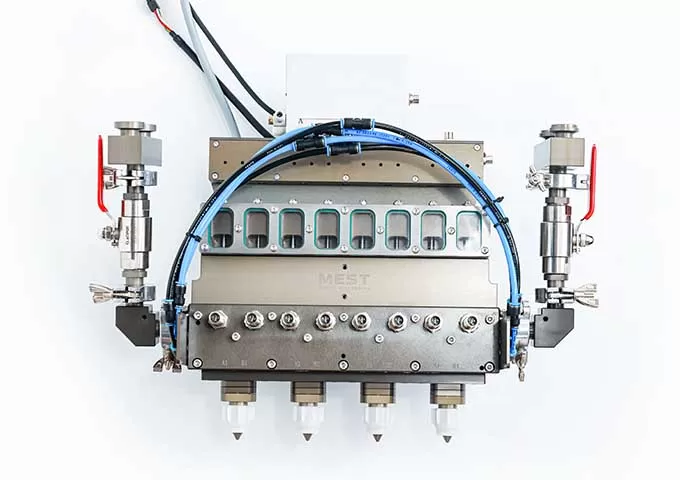

MEST Technology's dispensing solutions are engineered for unmatched precision and reliability, delivering consistent performance across diverse industries. Whether standard or customized, our dispensing adhesive systems meet the highest standards, ensuring optimal results every time.

Our dispensing system is designed for a wide range of applications across various industries. For example, our adhesive dispensing robot is ideal for precision bonding in the electronics and automotive sectors. And, our fluid dispensing equipment excels in medical device manufacturing, ensuring accurate and consistent application of bio-compatible materials. Our products are unique for businesses looking for reliable yet affordable options.

Our dedication to customer satisfaction goes beyond just the purchase. With comprehensive after-sales support, our expert team ensures smooth installation, prompt troubleshooting, and ongoing maintenance of your glue dispensing machine, helping you maximize its performance and longevity.

A dispensing machine can be considered as a type of fluid dispensing systems. Dispensing machine can include machines that dispense different substances such as solids, powders, and gases.

Adhesive dispensing systems provide sealing and bonding between materials by precisely dispensing adhesives or sealants, thereby ensuring the structural integrity and protective properties of components.

An adhesive dispenser machine protects sensitive components, such as electronics, by ensuring precise material application for insulation and durability.

An automatic dispensing machine uniformly coats surfaces for protection, aesthetics, or functionality.

Our auto dispenser machine dispenses materials into molds, cavities, or containers with unmatched accuracy, avoiding spills or overflows.

Various patterns can be customized according to customer needs to achieve high-precision micro-dispensing. Whether it is a complex geometric shape or tiny details, the glue dispensing equipment can ensure that every drop of glue reaches the designated position accurately.

Choosing the right glue dispensing machine involves several key considerations. First, assess the type and viscosity of the material to be dispensed. Next, determine the required accuracy and volume for your application. Consider the speed of adhesive dispensing and the production environment, including temperature and humidity. Evaluate compatibility with existing systems and the ease of integration. Additionally, factor in maintenance requirements and the availability of technical support. Finally, review regulatory compliance relevant to your industry. By carefully evaluating these factors, you can select the most suitable glue dispensing equipment for your specific needs.

There are two way. Firstly, you can send fluid samples and workpiece samples to our lab for testing, and we will issue reports and videos; secondly, for those fluids with hazardous chemicals that can not be mailed, we can look for similar fluids domestically, while you need to mail workpiece samples to us for tests.

Most of our glue dispensing systems have major spare parts in stock, and the lead time from purchase order to production is about 10 days. For customized automated dispensing systems, the L/T varies according to the configuration requirements, from 20 to 180 days are possible.

Generally, we have three ways for installation and debugging services:

Firstly, you can send employees to our headquarter in China to receive training, and we will arrange engineers to guide around the clock, the period is around 3-5 days.

Secondly, we can arrange engineers to travel to your site for glue dispensing machine installation and debugging, the cycle is generally 5-7 days. Thirdly, we deliver manuals and videos and guide you to install and debugging remotely.

As regards the service cost that will be generated, pls specifically consult our sales manager.